In today's diverse manufacturing landscape, the versatility of plastic sheets has made them an indispensable material across various industries. From construction to packaging, these sheets come in a multitude of types and sizes, each tailored to specific applications. As industry expert Dr. Emily Harper, a leading researcher in materials science, aptly states, "The right plastic sheet can enhance functionality and efficiency in ways that traditional materials simply cannot." This perspective underscores the significance of selecting the appropriate plastic sheet for any given project.

As we approach 2025, the advancements in plastic sheet technology continue to evolve, opening up new possibilities for innovation. Whether it involves high-impact resistance for protective barriers or lightweight options for easy transport, understanding the unique properties of different plastic sheets is essential for maximizing their benefits. The forthcoming sections will delve into the top plastic sheets available for every conceivable application, highlighting their features, advantages, and ideal use cases, thereby equipping you with the knowledge needed to make informed decisions for your projects.

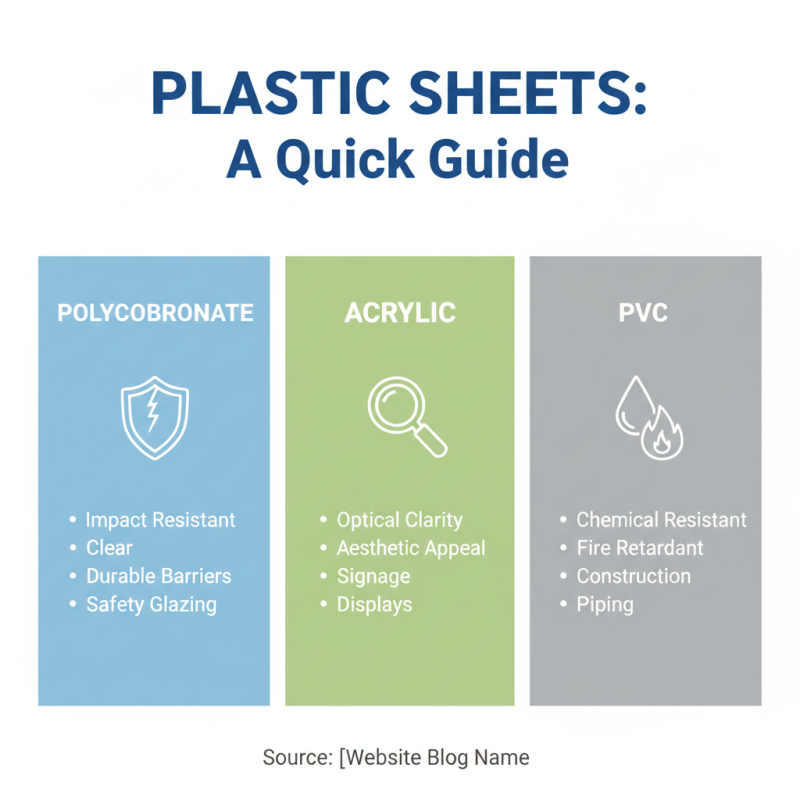

When selecting plastic sheets for various applications, it is essential to understand the different types of materials available and their unique properties. Commonly used plastics like polycarbonate, acrylic, and PVC each offer distinct advantages that cater to diverse needs. Polycarbonate sheets, known for their exceptional impact resistance and clarity, are ideal for applications requiring strong, durable barriers, such as in safety glazing and protective covers. On the other hand, acrylic sheets provide excellent optical clarity and aesthetic appeal, making them a preferred choice for signage and displays.

Another important material is PVC, which is widely used in construction and industrial settings due to its chemical resistance and affordability. It is often employed for applications such as wall coverings and protective barriers. Additionally, polypropylene and polyethylene sheets are recognized for their lightweight properties and flexibility, making them suitable for packaging, containers, and various other uses in both commercial and residential settings. Understanding the specific requirements of your project will ensure you select the most appropriate plastic sheet material to achieve optimal results.

In 2025, the landscape of plastic sheets has evolved significantly to meet diverse application demands across various industries. Key properties such as strength, durability, and chemical resistance have become paramount in the selection process. For instance, polycarbonate sheets are renowned for their exceptional impact resistance and optical clarity, making them ideal for applications in security and design. Meanwhile, acrylic sheets offer lightweight options with excellent weatherability, suitable for both indoor and outdoor uses.

Furthermore, polyethylene sheets have captured attention for their versatility and cost-effectiveness, often employed in packaging and protective applications due to their resistance to moisture and chemicals. On the other hand, polypropylene sheets are celebrated for their lighter weight and stiffness, making them suitable for automotive and structural purposes.

Understanding these key properties allows businesses and consumers to choose the appropriate plastic sheets for their specific needs, ultimately enhancing product effectiveness and performance in their respective fields.

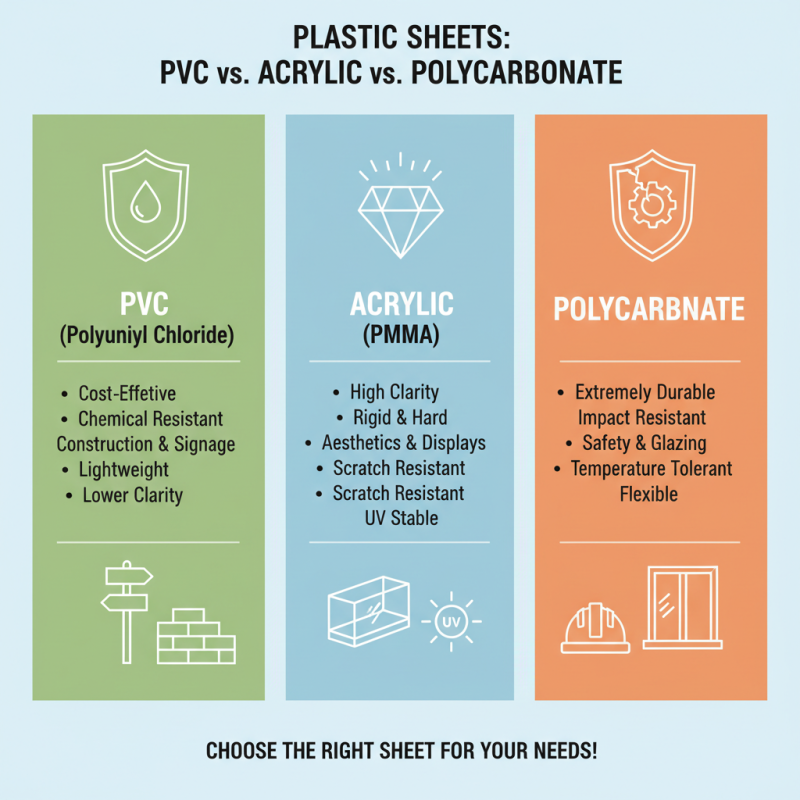

When selecting plastic sheets for various applications, three popular materials often come into play: PVC, acrylic, and polycarbonate. Each of these materials boasts unique properties that cater to different needs. PVC sheets are known for their cost-effectiveness and excellent chemical resistance, making them ideal for applications in the construction and signage industries. Their lightweight nature also facilitates easy handling and installation, though they may not offer the same level of clarity as their counterparts.

Acrylic sheets, on the other hand, are prized for their superior optical clarity and versatility. They can be easily fabricated into complex shapes, making them suitable for both indoor and outdoor uses, from display cases to skylights. However, while acrylic is durable, it is more prone to scratching compared to PVC, necessitating careful handling and maintenance.

Polycarbonate sheets offer a balance between strength and weight, featuring high impact resistance that surpasses both PVC and acrylic. This makes polycarbonate an excellent choice for environments where durability is paramount, such as in safety glazing or protective barriers. Although generally more costly, their longevity and ability to withstand extreme weather conditions make them a worthwhile investment for demanding applications.

Plastic sheets are becoming an essential component in various industrial and commercial applications due to their versatility, durability, and cost-effectiveness. According to a recent market analysis by Research and Markets, the global plastic sheets market is projected to reach USD 55 billion by 2025, driven by increasing demand across sectors such as construction, automotive, and packaging. This growth is indicative of the shift toward lightweight materials that not only enhance efficiency but also contribute to sustainability in manufacturing practices.

In the industrial sector, plastic sheets are utilized for a broad range of applications, including protective barriers, equipment covers, and components in assembly lines. Polycarbonate sheets, for instance, are renowned for their high impact resistance and clarity, making them ideal for safety glazing and signage. Furthermore, the use of acrylic sheets in manufacturing processes has increased by approximately 7% annually as companies seek to reduce weight without compromising strength. In commercial settings, plastic sheets are widely employed in architectural elements, display cases, and even furniture, showcasing their aesthetic appeal and functional versatility. As industries evolve, the innovative applications of plastic sheets continue to expand, highlighting their importance in contemporary manufacturing and design.

| Application | Plastic Sheet Type | Thickness (mm) | Strength (MPa) | Temperature Resistance (°C) |

|---|---|---|---|---|

| Packaging | Polyethylene (PE) | 0.5 | 14 | -40 to 85 |

| Construction | Polycarbonate (PC) | 3 | 70 | -40 to 120 |

| Signage | Acrylic (PMMA) | 5 | 85 | -30 to 90 |

| Automotive | Polypropylene (PP) | 2 | 30 | -20 to 100 |

| Medical | Polyvinyl Chloride (PVC) | 1 | 50 | -15 to 60 |

As industries continue to seek sustainable solutions, the future trends in plastic sheet manufacturing are shifting towards more eco-friendly practices and materials. The increasing awareness of environmental issues has propelled manufacturers to invest in biodegradable and recyclable options. Advances in material science are paving the way for innovative plastics that minimize the carbon footprint while retaining strength and durability. The integration of renewable resources into plastic formulations is becoming a standard practice, thereby reducing reliance on fossil fuels and enhancing the sustainability profile of these materials.

Moreover, the use of advanced manufacturing techniques, such as 3D printing and injection molding, is transforming the way plastic sheets are produced. These methods not only increase efficiency and reduce waste but also allow for customization to meet specific application needs. The emphasis on closed-loop recycling systems is gaining traction, where discarded plastic sheets are reprocessed to create new products, contributing to a circular economy. This approach not only conserves resources but also reduces landfill waste, aligning the plastic sheet industry with broader sustainability goals.

As innovations continue to emerge, plastic sheets are expected to play a pivotal role in various sectors, from construction to packaging, all while prioritizing environmental responsibility.