In 2026, PVC sheets continue to gain popularity across various industries. Many people discover their versatile applications and unique benefits. PVC sheets offer durability, flexibility, and moisture resistance. These features make them ideal for diverse projects, from construction to crafts.

While PVC sheets are praised for their advantages, some drawbacks are worth noting. The production process raises environmental concerns. Additionally, the material may not be suitable for every application. Careful consideration is needed to avoid potential waste or inefficiencies.

As we explore the uses of PVC sheets, it’s crucial to understand both the benefits and limitations. Knowing these factors helps customers make informed decisions. Whether for home improvement or industrial use, PVC sheets offer a myriad of possibilities. Understanding their role can lead to better outcomes in various projects.

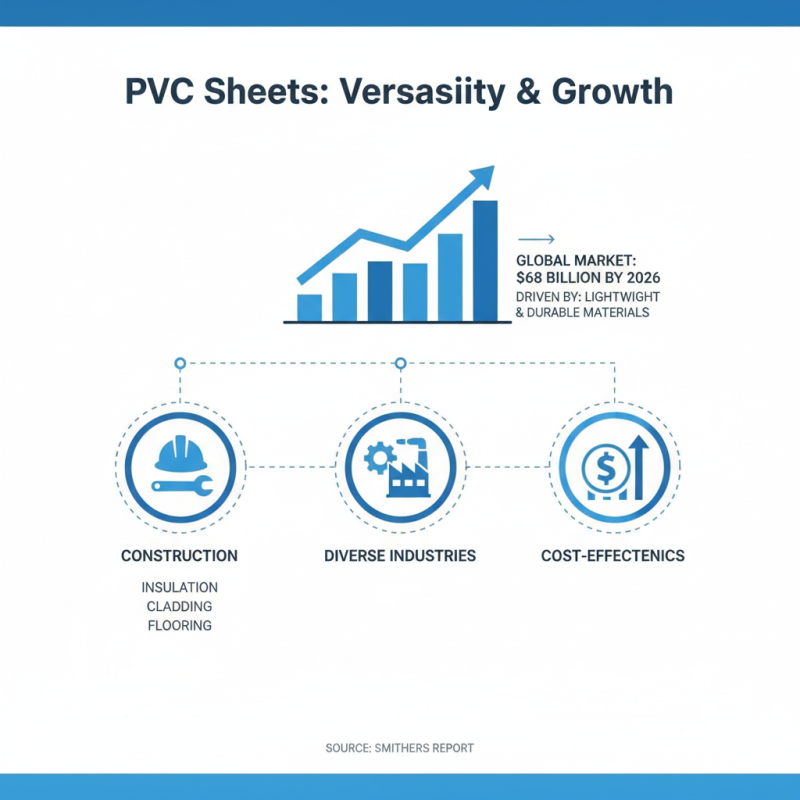

PVC sheets are widely used across diverse industries due to their versatility and cost-effectiveness. The construction sector employs PVC sheets for insulation, cladding, and flooring. According to a recent report by Smithers, the global PVC market is projected to reach $68 billion by 2026. This growth is driven by increased demand for lightweight and durable materials.

In the healthcare industry, PVC sheets play a critical role. They are used in medical devices and sterile packaging. A study indicated that PVC can easily be sterilized, which is crucial for safety. However, concerns over the environmental impact of PVC production are rising.

Packaging is another significant application. PVC sheets serve as protective barriers for food and consumer goods. The flexible nature of these sheets helps enhance product visibility while maintaining durability. Yet, the recycling of PVC remains a challenge. The industry must address these environmental considerations to ensure sustainable practices in the coming years.

PVC sheets have gained popularity for various construction and design applications. They are lightweight and easy to handle, making them suitable for different projects. Their durability is one of the primary reasons they are chosen. Unlike wood or metal, PVC is resistant to moisture and corrosion. This resilience can lead to lower maintenance costs over time.

In design contexts, PVC sheets offer versatility. They can be easily cut, shaped, and colored. This flexibility allows architects and designers to create stunning visuals. However, the aesthetic appeal sometimes comes at the cost of environmental concerns. Although PVC can last long, its production raises questions about sustainability. Careful consideration is necessary when selecting materials to balance creativity and ecological impact.

The benefits of PVC sheets extend to insulation properties as well. They can help maintain temperature in buildings effectively. This can lead to energy savings, a critical consideration in modern construction. However, relying solely on PVC can feel limiting. Exploring alternative materials alongside PVC may offer broader design possibilities. Embracing these challenges can lead to more innovative solutions in construction and design.

| Use Case | Benefits | Applications | Sustainability |

|---|---|---|---|

| Wall Panels | Durable, moisture-resistant, easy to clean | Commercial and residential buildings | Recyclable material, reduces waste |

| Roofing Sheets | Lightweight, UV resistant, cost-effective | Industrial and agricultural buildings | Long lifespan with reduced environmental impact |

| Flooring | Comfortable underfoot, slip-resistant, easy maintenance | Homes, schools, hospitals | Low VOC emissions, contributes to healthier indoor air quality |

| Packaging Material | Lightweight, versatile, moisture-resistant | Food and non-food product packaging | Recyclable and reusable options |

| Signage | Weather-resistant, durable, vibrant color options | Retail, events, outdoor advertising | Long-lasting, reduces material turnover |

PVC sheets are versatile materials used in many industries. However, their environmental impact is a pressing concern. The production of PVC requires non-renewable resources and generates harmful chemicals. These byproducts can pollute air and water. It’s crucial to acknowledge that while PVC is durable, this comes at a cost to the environment.

Recycling options for PVC are limited, but growth is expected. Companies now explore ways to use recycled PVC sheets. Innovations in this area show promise. Still, challenges remain in establishing effective recycling facilities. The lifespan of PVC products can also be a double-edged sword. Long-lasting materials contribute to waste if not disposed of properly.

Consumer awareness plays a vital role. Individuals should consider alternatives or ensure proper disposal of PVC products. Educating others about their choices can help reduce the negative impact. Understanding the full lifecycle of PVC sheets is essential for responsible usage. As we move towards sustainability, every effort counts, yet much work still needs to be done.

PVC sheets are gaining popularity as a versatile material commonly used in various applications, from signage to construction. They stand out compared to other materials like acrylic and polycarbonate. PVC sheets are more affordable and lighter than many alternatives. This makes them easier to handle and transport. In many instances, their durability is adequate for projects that don’t require extreme toughness.

However, there are limitations. While PVC is resistant to moisture and chemicals, it may not be as impact-resistant as polycarbonate sheets. In high-stress environments, choosing the right material is crucial. The clarity of acrylic sheets often surpasses that of PVC, making them preferable for display cases. Yet, PVC has greater flexibility in applications where bending is required.

Upon reflection, PVC sheet usage has both advantages and drawbacks. It’s important to consider the specific needs of your project. While PVC can offer cost savings, it’s necessary to balance that with the potential need for higher performance materials. Choosing the right sheet material often involves trade-offs. Understanding these factors will lead to better decisions in material selection for diverse applications.

The PVC sheet market is set to undergo significant changes by 2026. According to a recent report by Grand View Research, the global demand for PVC sheets is expected to grow at a CAGR of 4.5%. This growth is driven by increasing applications in construction, healthcare, and automotive industries. The lightweight nature of PVC sheets makes them an appealing choice for many.

In 2026, eco-friendly PVC alternatives are expected to gain traction. Sustainable production methods will likely dominate, as consumers seek greener options. For example, recycled PVC can reduce environmental impact and lower production costs. This trend reflects growing consumer awareness about sustainability.

Innovations in manufacturing technology are also on the horizon. Advanced processes may enhance the strength and durability of PVC sheets. However, challenges will persist. Ensuring quality while scaling up production remains a concern for manufacturers. Balancing cost and sustainability will be crucial as new players enter the market. Thus, the future of PVC sheets is both promising and complex.