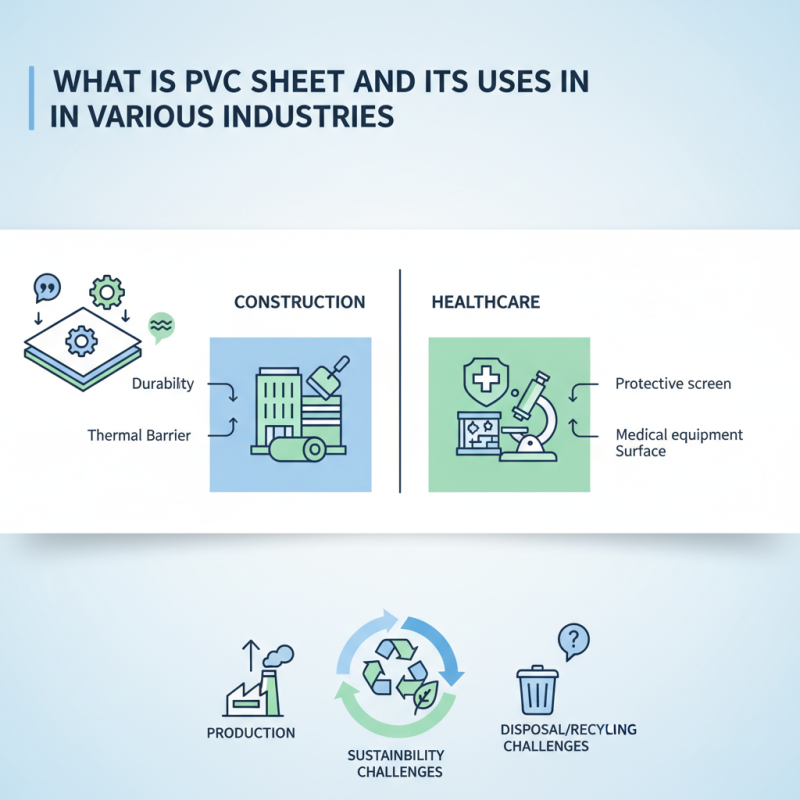

PVC sheets are versatile materials widely used across numerous industries. According to industry expert Dr. Sarah Thompson, "PVC sheets provide an unmatched combination of durability and flexibility." These qualities make them ideal for various applications, from construction to healthcare.

In construction, PVC sheets are often used as wall coverings and insulation materials. They are lightweight and easy to install, enabling quicker project completion. In healthcare, they are utilized for protective barriers and equipment surfaces due to their hygienic properties. However, one must consider the environmental impact of PVC production and disposal.

Businesses increasingly explore sustainable alternatives, yet PVC sheets remain prevalent. The challenges of recycling and the use of additives complicate the environmental conversation. It's important to reflect on the balance between utility and sustainability in the use of PVC sheets.

PVC sheets are versatile and widely used in various industries. These sheets are made from polyvinyl chloride, a synthetic plastic polymer. The composition includes both additives and stabilizers, enhancing their durability and flexibility. This combination makes PVC sheets resistant to moisture, chemicals, and UV light.

Tips: When choosing PVC sheets, consider the specific needs of your project. Think about thickness and surface texture, as these can greatly affect performance and aesthetics.

In construction, PVC sheets serve multiple purposes. They are often used for wall panels, flooring, and roofing due to their robustness. However, not every type of PVC is suited for all applications. It’s essential to assess the environment where the sheets will be installed.

Tips: Pay attention to the sheet's finish. A smooth surface may be easier to clean, while textured surfaces can add grip. Each choice presents unique trade-offs and requires careful thought.

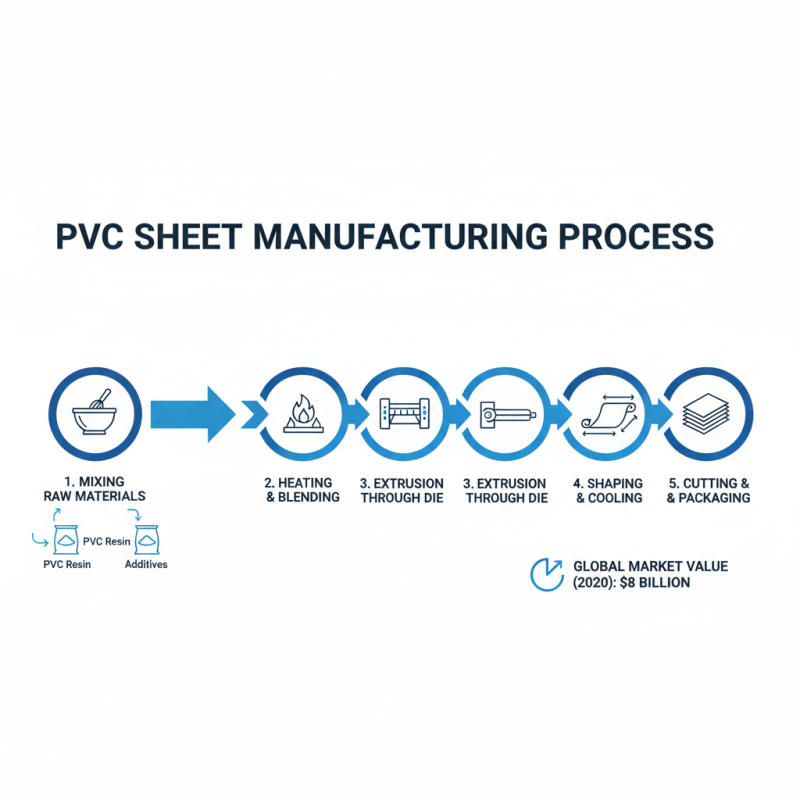

The manufacturing process of PVC sheets involves several key steps. First, raw materials like polyvinyl chloride resin and additives are mixed. This mixture is heated to form a homogeneous blend. The blend is typically extruded through a die to create a continuous sheet. This method allows precise control over thickness and texture. According to industry reports, the global PVC sheet market was valued at approximately $8 billion in 2020, highlighting the material's wide application and demand.

After extrusion, the sheets undergo cooling and are cut to size. Quality control is crucial during production. Minor flaws can impact the final product's performance. Some PVC sheets are later treated with surface coatings for better durability. In a recent survey, about 40% of manufacturers reported challenges in achieving consistent thickness. This inconsistency can lead to waste and increased production costs.

Moreover, the recycling of PVC sheets remains a challenge. While some facilities have systems in place, many still lack effective recycling methods. As sustainability grows in importance, the industry faces pressure to improve these processes. Efforts to innovate in reductions and reuse are ongoing but require more robust solutions.

PVC sheets are widely recognized for their versatility and utility across various industries. One prominent property of PVC sheets is their excellent chemical resistance. They can withstand exposure to numerous acids and alkalis without degrading. This makes them ideal for environments like laboratories and chemical processing plants. The durability of PVC sheets also lends itself well to harsh weather conditions, making them suitable for outdoor applications.

Another notable benefit is their lightweight nature, which simplifies handling and installation. PVC sheets can be easily cut, shaped, and fabricated into different forms. This flexibility enhances their use in construction and signage. Their smooth surface can be used for printing, making them popular for advertising displays. However, the environmental impact of PVC production raises important questions. This aspect needs reflection as industries seek more sustainable materials.

In addition, PVC sheets come in various colors and thicknesses, appealing to aesthetic demands. Their insulation properties can provide energy savings in buildings, but these gains must be balanced against potential drawbacks. Some people worry about the long-term health effects of PVC products. Careful consideration of these factors ensures better adoption and reduced environmental footprint.

PVC sheets are versatile materials widely used in the construction industry. These sheets are light yet durable. Their resistance to moisture makes them ideal for various applications. In construction, they serve multiple purposes, like wall cladding and roofing. Builders often prefer them for their ease of installation. However, not all installations go smoothly. Proper cutting and fitting techniques are crucial.

In addition to wall and roof applications, PVC sheets are used for flooring. They provide a waterproof layer that is easy to clean. This quality is especially valuable in areas prone to spills. Some projects may face challenges like improper adhesion. This can lead to peeling or bubbling over time. Regular maintenance can help mitigate these issues.

Moreover, PVC sheets can also be used for signage in construction zones. Clear visibility is essential for safety. Yet, if they are not secured properly, they might flutter or fall. This requires attention during the installation phase. Overall, PVC sheets are a practical choice in construction but demand careful handling.

PVC sheets are versatile materials widely used in packaging and signage. Their durability and lightweight nature make them ideal for various industrial applications. In the packaging sector, PVC sheets serve as protective covers for products. They can be easily molded into different shapes and sizes. This capability allows manufacturers to create unique packaging solutions that meet specific needs.

In the signage industry, PVC sheets are often utilized for both indoor and outdoor signs. They can withstand various weather conditions, ensuring longevity. The surface is smooth, allowing for vibrant prints and clear visibility. Businesses can display their brand messages effectively using these sheets. However, there is a challenge in ensuring the quality of prints. Poor printing methods can lead to fading and degradation over time.

When considering PVC sheets, one must also think about environmental impact. These materials are not biodegradable, raising concerns about waste. Companies need to reflect on responsible use and disposal practices. Balancing functionality and sustainability is crucial in today's industrial landscape.

This chart illustrates the distribution of PVC sheet usage across various industries. The largest segment is in packaging, followed by construction, indicating a high demand for PVC sheets in these areas.