When it comes to selecting the right PVC sheet for your manufacturing needs, the importance of informed decision-making cannot be overstated. According to a recent market research report by Smithers, the global PVC sheet market is projected to reach $18.5 billion by 2025, driven by its increasing applications in various industries such as construction, automotive, and packaging. These trends highlight the necessity for manufacturers to choose high-quality PVC sheets that align with their specific requirements. Factors such as thickness, finish, and chemical resistance must be carefully considered to ensure optimal performance and durability. This blog will provide industry insights and practical examples to guide you in making the best choice of PVC sheet, ultimately enhancing your manufacturing processes and product offerings.

When selecting the best PVC sheet for your manufacturing needs, it is crucial to understand the different types available and their specific applications. PVC sheets come in various formulations, each tailored for distinct uses. For instance, rigid PVC sheets are ideal for applications requiring structural integrity, such as signage and display fixtures. Their rigidity provides excellent stability, making them a favorite in the construction and advertising industries.

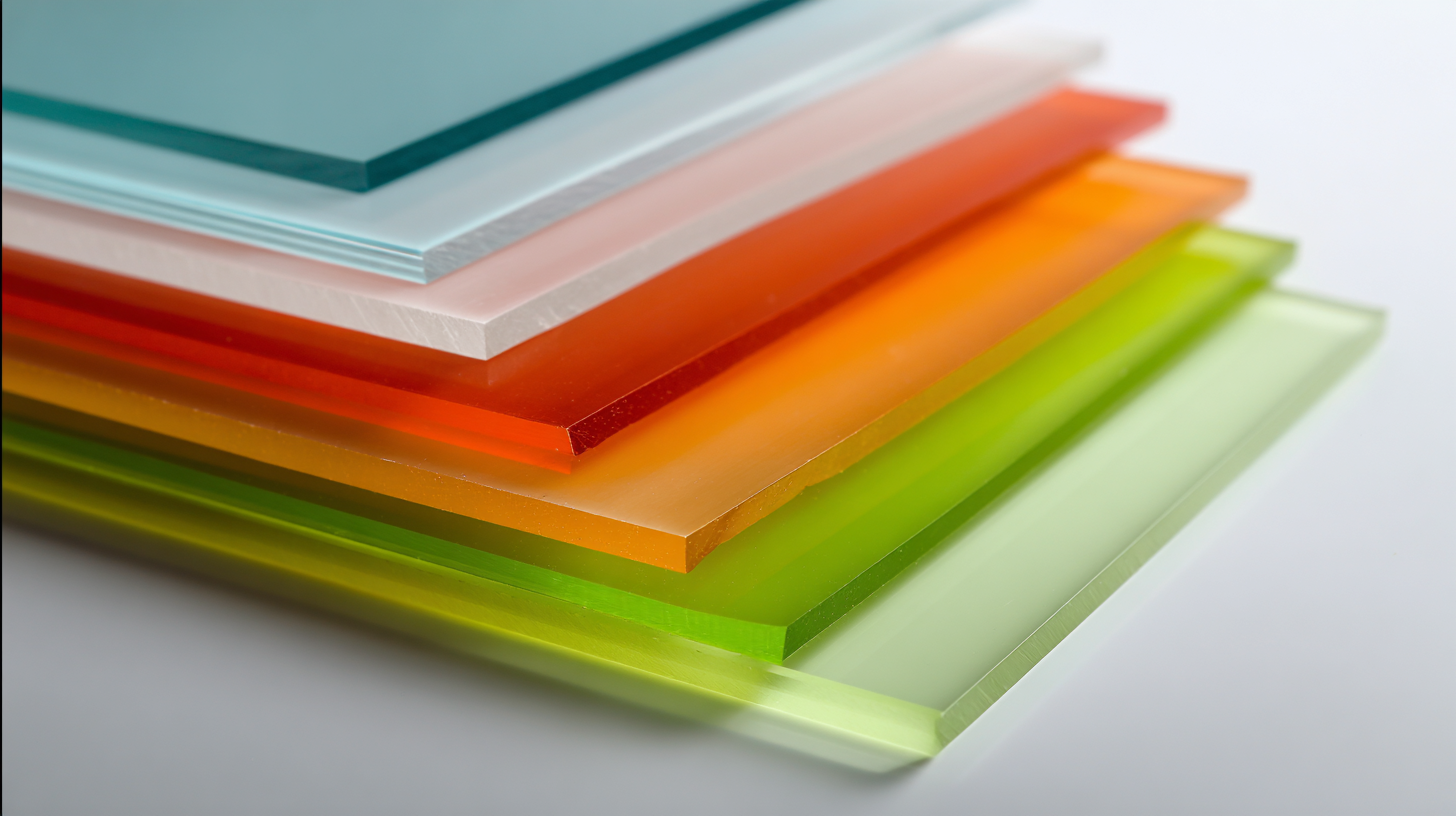

On the other hand, flexible PVC sheets are used in applications where bendability is necessary. These sheets are commonly employed in the production of bags, covers, and various protective sheeting. Their versatility allows them to be manufactured in various colors and finishes, catering to aesthetic requirements while maintaining functionality. Additionally, foamed PVC sheets are lightweight yet sturdy, perfect for lightweight signage and decorative applications. Understanding these distinctions helps manufacturers make informed decisions that enhance productivity and meet industry standards.

| Type of PVC Sheet | Thickness (mm) | Common Applications | Advantages |

|---|---|---|---|

| Rigid PVC Sheet | 1.5 - 12 | Signage, Industrial Applications, Packaging | Durable, Impact Resistant, Easy to Fabricate |

| Flexible PVC Sheet | 0.5 - 6 | Clothing, Bags, Electrical Insulation | High Flexibility, Soft Touch, Versatile |

| Foamed PVC Sheet | 3 - 19 | Interior Decor, Displays, 3D Letters | Lightweight, Good Insulation, Sandable |

| High-impact PVC Sheet | 2 - 10 | Automotive Parts, Medical Devices | Excellent Impact Resistance, Strong, Durable |

| Anti-static PVC Sheet | 1 - 5 | Electronics Packaging, Clean Rooms | Prevention of Static Charge, Safe for Electronics |

When selecting PVC sheets for your manufacturing needs, several key factors come into play that can significantly impact both production efficiency and product quality. First, consider the thickness and flexibility of the PVC sheet. Thicker sheets are typically more durable and can withstand higher pressures, making them suitable for heavy-duty applications. Conversely, for projects requiring intricate designs or bends, thinner and more flexible sheets might be more appropriate. Evaluating the specific requirements of your manufacturing process is essential in determining the optimal thickness.

Another crucial factor is the type of PVC — either rigid or flexible. Rigid PVC is often used for structural applications, while flexible PVC is ideal for products that need to be easily manipulated or formed. Additionally, assess the environmental considerations associated with the PVC sheet. Many manufacturers now offer eco-friendly options that reduce the environmental impact without compromising on quality. By focusing on aspects such as thickness, type, and sustainability, you can select the right PVC sheet that aligns perfectly with your manufacturing requirements.

When selecting the best PVC sheet for your manufacturing needs, it's crucial to consider the specific requirements of your industry. Different applications necessitate varying grades and properties of PVC sheets. For instance, the food industry demands high compliance with safety standards, often requiring sheets that are both FDA-approved and easy to clean. In contrast, the construction sector might prioritize durability and weather resistance, calling for thicker sheets with added UV stability to withstand external elements.

Moreover, the healthcare industry requires PVC sheets that are not only sterile but also resistant to chemicals and easy to sanitize. In this sector, the flexibility of the material can be just as important as its rigidity, depending on the application. Conducting a comparative analysis of these industry-specific requirements can help manufacturers make informed decisions that align with their operational needs, ensuring optimal performance and compliance. By understanding the unique demands of each sector, you can effectively choose the right PVC sheet that enhances productivity while meeting regulatory standards.

When selecting the best PVC sheets for your manufacturing needs, understanding the durability and performance standards is crucial. Quality PVC sheets are designed to withstand a range of environmental conditions and stresses. It’s essential to assess the thickness, formulation, and finish of the sheets, as these factors directly impact their longevity and performance. Look for PVC sheets that have been tested for impact resistance, UV stability, and chemical resistance to ensure they will meet the demands of your specific manufacturing processes.

Moreover, industry standards play a significant role in determining the quality of PVC sheets. Compliance with regulations such as ASTM, ISO, and other relevant industry benchmarks can provide assurance that the sheets you choose will perform reliably over time. Ensuring that your supplier adheres to these standards can help avoid complications related to failures or defects in production. Investing in high-quality PVC sheets not only guarantees durability but also enhances the overall efficiency of your manufacturing operations, leading to better end products.

When choosing the best PVC sheet for your manufacturing needs, understanding the balance between cost-effectiveness and quality is crucial. PVC materials can vary widely in terms of price and performance, making it essential to assess your specific applications. Industry insights suggest that while budget-friendly materials may save upfront costs, they can lead to higher long-term expenses due to potential durability issues or performance limitations. For example, utilizing high-quality PVC sheets may require a larger initial investment, but they often provide superior longevity and resilience, reducing frequent replacements and maintenance costs.

Additionally, evaluating the different PVC options available can uncover cost-effective solutions that do not compromise on quality. Recent market reports on PVC manufacturing point towards emerging trends that emphasize both affordability and performance. Understanding the latest technological innovations in PVC production can give manufacturers leverage in selecting materials that meet both budgetary constraints and performance specifications, enhancing overall production efficiency. Making an informed decision involves not only comparing initial costs but also considering the long-term benefits of investing in quality PVC products.