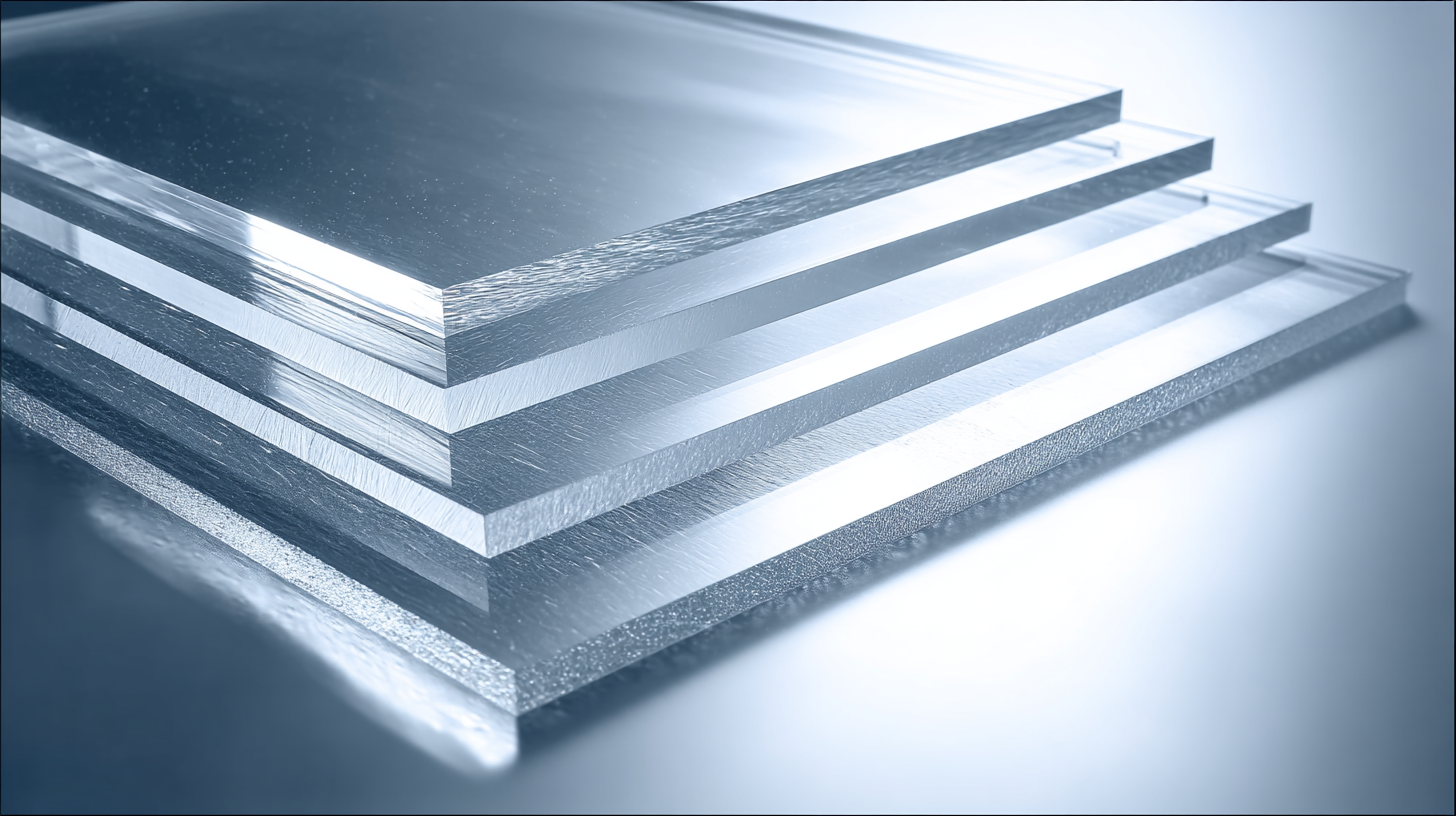

When embarking on a new project, selecting the right materials can significantly influence both the outcome and longevity of your work. Among the myriad of options available, Plastic Sheets stand out as versatile and durable solutions for a variety of applications. This blog will explore the key characteristics and suitability of different types of plastic sheets, helping you make informed decisions tailored to your specific needs. From the clarity of acrylic sheets to the robustness of polycarbonate, each type has its unique benefits and ideal use cases.

Whether you're a DIY enthusiast or a professional contractor, understanding the diverse properties and applications of plastic sheets will empower you to choose the best option for your next endeavor. Join us as we delve into the world of plastic sheets and guide you on how to effectively select the right material for your project.

Choosing the right plastic sheets for your project requires a clear understanding of the various types and their specific applications. There are several common types of plastic sheets, including acrylic, polycarbonate, PVC, and polyethylene. Each type offers unique benefits; for instance, acrylic sheets are known for their excellent clarity and impact resistance, making them ideal for applications like display cases or skylights.

Polycarbonate, on the other hand, is highly durable and can withstand extreme temperatures, making it perfect for industrial use or outdoor signage.

Polycarbonate, on the other hand, is highly durable and can withstand extreme temperatures, making it perfect for industrial use or outdoor signage.

When selecting plastic sheets, consider not only the mechanical properties but also the environmental exposure they will face. For heavy-duty applications, such as in construction or vehicle manufacturing, PVC and polyethylene sheets are often favored due to their strength and moisture resistance. On the other hand, for aesthetic applications where visibility and light transmission are key, acrylic sheets are generally preferred. By understanding the specific characteristics and uses of each type, you can make an informed decision that ensures the success of your project.

When selecting plastic sheets for your next project, several key factors should guide your decision. First and foremost, understand the different types of plastic materials available—polycarbonate, acrylic, and PVC are among the most commonly used. According to a report by Grand View Research, the global acrylic sheet market size was valued at approximately $2.02 billion in 2020 and is projected to grow at a CAGR of 5.5% from 2021 to 2028. This growth is driven by the material's exceptional clarity, lightweight properties, and impact resistance, making it ideal for a wide range of applications.

Another critical consideration is the specific properties of the sheets, such as UV resistance, thickness, and temperature tolerance. For instance, polycarbonate sheets can withstand extreme temperatures and are virtually unbreakable, which is essential for outdoor applications. A study by the Plastics Industry Association indicates that the demand for high-performance plastic materials, particularly for construction and automotive uses, has increased significantly—projected growth rates nearing 4.5% annually. These trends suggest that selecting the right kind of plastic sheet not only depends on performance but also on adhering to industry standards that ensure durability and efficiency for your project.

This chart compares the tensile strength of various types of plastic sheets, helping you to choose the best material for your project based on strength requirements.

When selecting plastic sheets for your next project, understanding the role of material thickness is crucial for ensuring durability. Studies indicate that thicker sheets generally offer increased resistance to impacts and environmental factors such as UV radiation and temperature variations. For example, a report by the Plastic Industry Association highlights that sheets with a thickness of 0.5 inches or more can withstand heavier loads and are less prone to warping and cracking, making them ideal for construction and outdoor applications.

Tips: When assessing the thickness required, consider the specific demands of your project. For tasks requiring flexibility, such as signage, a sheet thickness of around 0.08 inches might suffice. However, for structural uses, a thickness of at least 0.25 inches is recommended for optimal performance.

In addition to thickness, the choice of material plays a critical role in the durability of plastic sheets. Polycarbonate sheets, for instance, offer superior impact resistance, being nearly 250 times stronger than glass. A study by the American Composites Manufacturers Association suggests that selecting the right thickness, along with the right type of plastic, can significantly extend the lifespan of your project.

Tips: Always consider environmental factors and potential wear and tear when choosing thickness; opt for thicker layers in high-stress environments to minimize maintenance costs and project lifespan.

When embarking on a project that requires plastic sheets, considering cost-effectiveness is paramount. Various types of plastic sheets come with distinct price points, and understanding these differences can significantly impact your budgeting. For example, polycarbonate sheets are known for their durability and versatility, making them a popular choice despite being one of the more expensive options. However, if your project does not require high impact resistance, opting for acrylic sheets can provide a more budget-friendly alternative without sacrificing too much in terms of clarity and aesthetic appeal.

Another aspect to consider is the thickness and size of the sheets. Thicker sheets often come at a premium, yet they can offer better long-term value if your project demands resilience. Additionally, purchasing larger sheets can reduce waste and lower overall costs. By assessing the specific requirements of your project and comparing them with the characteristics and prices of various plastic options, you can make an informed decision that aligns with your financial plan while still achieving satisfactory results.

When sourcing plastic sheets for your projects, understanding quality assurance in manufacturing is crucial, especially in the context of Chinese production. The recent issuance of the "Quality Power Construction Outline" by the Central Committee of the Communist Party of China and the State Council emphasizes the importance of adhering to national standards and certifications. This endeavor aims to promote high-quality development across various sectors, including materials like plastic sheets, which can significantly impact project outcomes.

To ensure you select the best plastic sheets, look for certifications that verify compliance with established quality standards. For instance, the 2023 global testing, inspection, and certification market is projected to grow from $362.34 billion in 2023 to $515.72 billion by 2032, reflecting a compound annual growth rate of 4%. Investing in certified materials not only guarantees durability but also signifies adherence to industry norms, which can be a deciding factor for project success.

Tips: